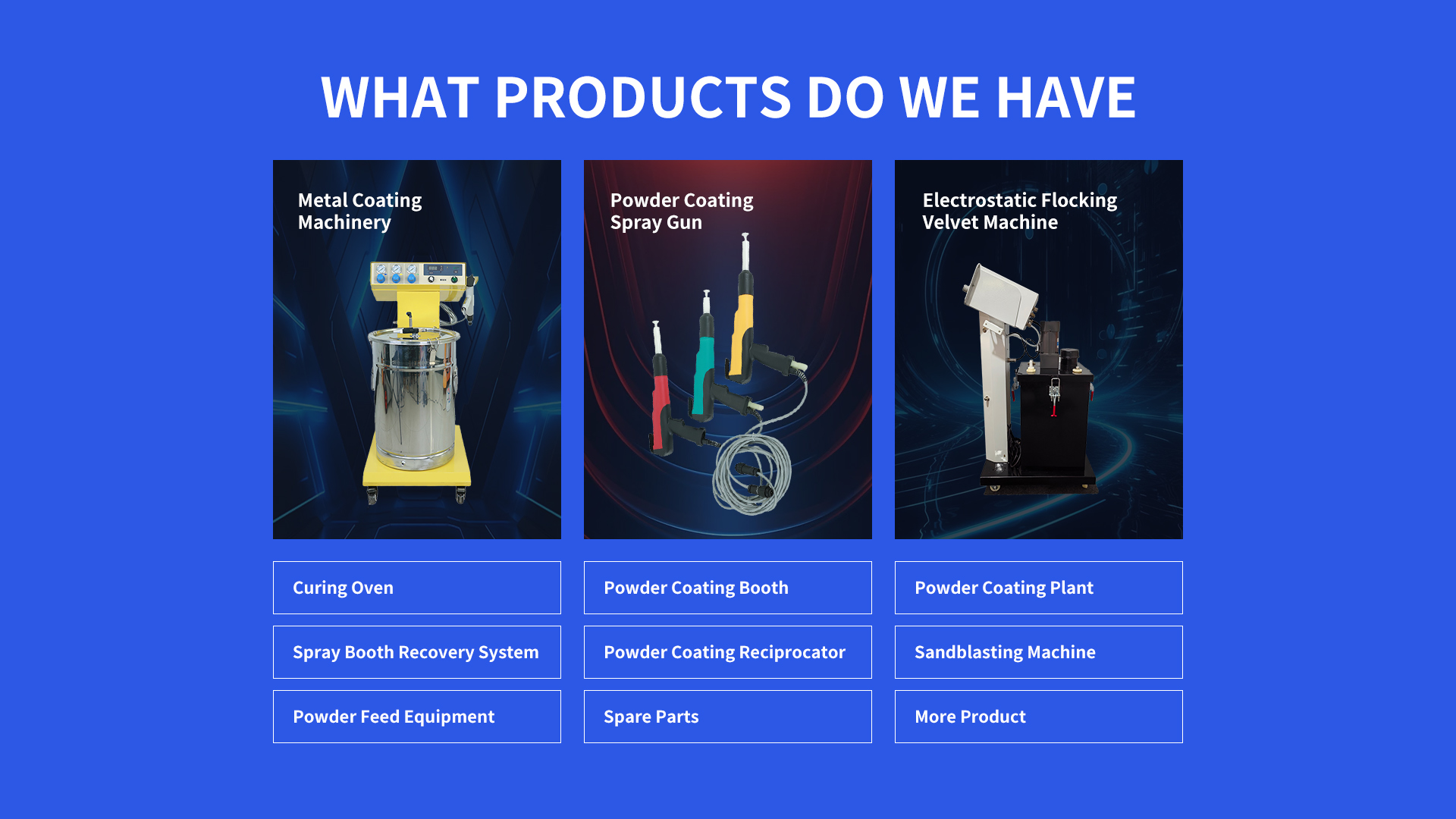

1. Automatic Powder Coating Line Equipment and Components

An Automatic Powder Coating Line integrates pretreatment systems, robotic spray guns, high-speed curing ovens, and programmable conveyor systems. Pretreatment stages include automated washing, chemical treatment, and drying to ensure surface readiness. Robotic arms equipped with electrostatic spray guns apply powder with precision, minimizing overspray. Infrared or convection ovens cure coatings at 170–210°C, while conveyors synchronize workflow for mass production. This setup maximizes throughput and consistency, reducing human intervention.

2. Automatic Powder Coating Line Applications

Automotive manufacturers use automatic lines for coating car bodies, wheels, and engine parts. Appliance producers apply them to refrigerators, washing machines, and ovens. The technology also serves aerospace components, metal furniture, and agricultural machinery. High-volume industries benefit from rapid cycle times and uniform finishes, critical for meeting strict quality standards.

3. Automatic Powder Coating Line Cost Analysis

Prices range from 100,000forsemi−automaticsystemstoover2 million for fully robotic lines. Key cost factors include conveyor length, oven capacity, and automation level. Energy-efficient ovens and powder recovery systems add 10–20% to upfront costs but cut long-term energy and material waste by 30–50%.

4. Operating an Automatic Powder Coating Line

Program robots to adjust spray patterns based on part geometry. Maintain oven temperature within ±5°C of the powder’s curing range. Optimize conveyor speed to balance throughput and curing time. Use integrated sensors to monitor powder thickness and trigger automatic adjustments. Schedule daily cleaning of spray booths and weekly maintenance of robotic arms.

5. How to Select an Automatic Powder Coating Line

Assess production volume, part size, and coating complexity. For large-scale operations, prioritize lines with multi-axis robots and real-time monitoring. Smaller facilities may opt for modular systems with upgradable automation. Choose suppliers offering remote diagnostics, training, and compliance with ISO 9001 or OSHA standards.

6. Safety in Automatic Powder Coating Lines

Install safety barriers around robotic arms to prevent accidents. Use explosion-proof equipment in spray zones. Ensure proper grounding to avoid electrostatic hazards. Implement dust extraction systems to reduce airborne particles. Train staff on emergency stop protocols and routine equipment lockout procedures.

7. Design Advantages of Automatic Powder Coating Lines

Automation reduces labor costs by 60–80% and ensures coating uniformity. Advanced powder recovery systems reclaim 95% of overspray, slashing material costs. Modular designs allow integration with existing production lines. Energy-efficient ovens with heat recovery cut power consumption by 25%, supporting sustainability goals.

8. Automatic Powder Coating Line FAQs

Q: What industries benefit most from automatic powder coating lines?

A: High-volume sectors like automotive and appliance manufacturing rely on automatic lines for speed and precision.

Q: How to minimize downtime in automatic coating systems?

A: Predictive maintenance and IoT-enabled monitoring tools alert operators to potential issues early.

Q: Are automatic lines suitable for small batches?

A: Yes, programmable settings allow quick changeovers for custom jobs.

Q: What reduces coating defects in automatic systems?

A: Consistent spray distance, optimized robot paths, and real-time thickness sensors.

Q: Can automatic lines handle mixed materials?

A: Yes, with adjustable parameters for metals, alloys, or pre-treated plastics.

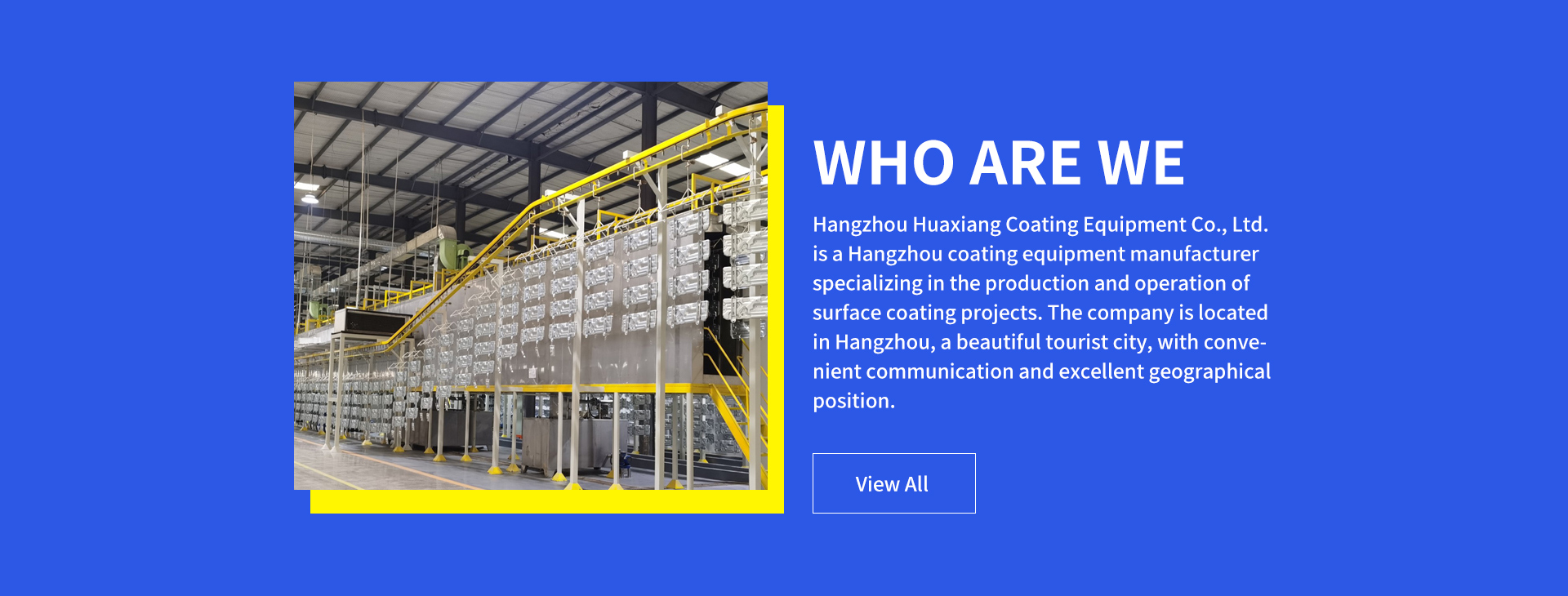

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com